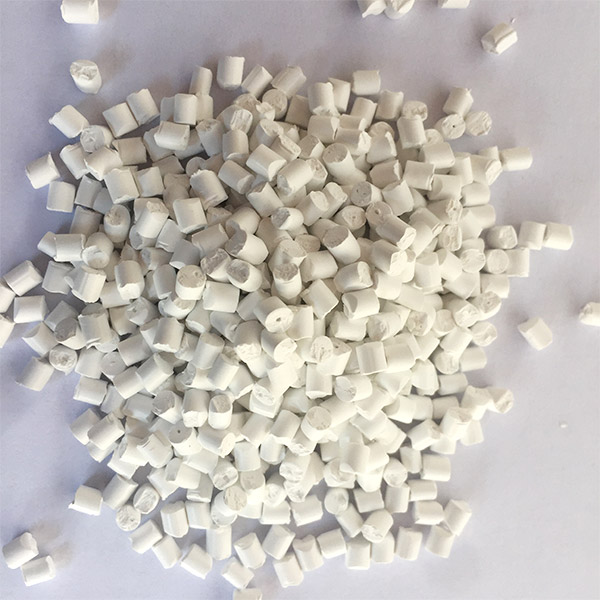

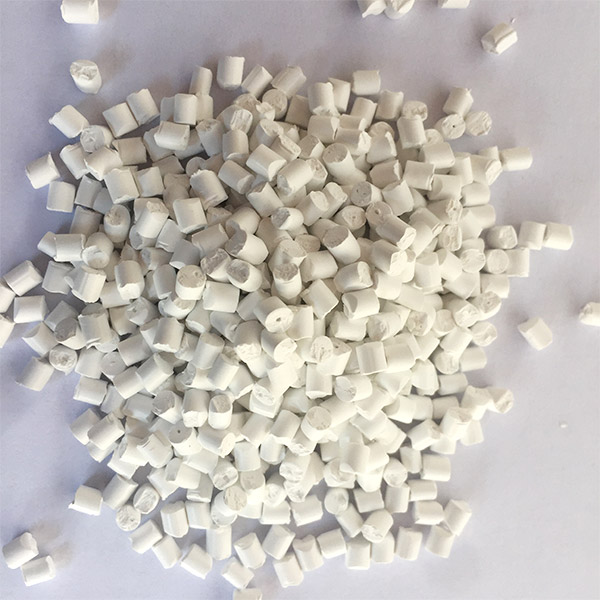

What are the requirements for the production of color masterbatch? This is a big puzzle for many friends who are just engaged in or want to be engaged in the production of color masterbatch. To explain this problem, we begin with the requirement of colour masterbatch.

1. Requirements for masterbatch pigments The matching relationship between pigments and plastics raw materials and auxiliaries must be paid attention to. The selection points are as follows.

(1) Colors can not react with resins and various additives. They have strong solvent resistance, small migration and good heat resistance. In other words, color masterbatches can not participate in various chemical reactions. For example, carbon black can control the curing reaction of polyester plastics, so carbon black can not be added to polyester. Because of the high processing temperature of plastic products, the color material should not decompose and discolor at the heating temperature.

Generally, inorganic pigments have good heat resistance, while organic pigments and dyes have poor heat resistance, which should be paid enough attention to when choosing color varieties. Click on the bottom left corner to read the original text, one click to purchase EC5011A breathable particles!

(2) The dispersibility and dyeing power of the pigments should be good. When the color is not uniformly dispersed, it will affect the appearance of the product; when the dyeing power is poor, it will increase the amount of color and material cost. The dispersibility and dyeing power of the same colour in different resins are different, so we should pay attention to this when choosing the colour. The particle size of pigments is also related to dispersion. The smaller the particle size of pigments, the better the dispersion and the stronger the dyeing power.

(3) We should understand the other properties of pigments, such as non-toxic pigments for plastic products used in food and children's toys; good electrical insulation pigments for plastic products used in electrical appliances; and good weather-aging resistant pigments for outdoor plastic products. 2. The technological process of colour masterbatch production is very strict. Generally, the wet process is adopted.

Colour masterbatch is prepared by water grinding, phase inversion, washing, drying and granulation. Only in this way can the product quality be guaranteed. In addition, a series of tests should be carried out to determine the fineness of the mortar, the diffusivity of the mortar, the solid content of the mortar and the fineness of the color slurry.

There are four ways to produce masterbatch.

Ink method, as its name implies, is the production method of ink paste in the production of masterbatch, that is, through three rolls of grinding, a layer of low molecular weight protective coating is coated on the surface of the pigment. After grinding, the fine color paste is mixed with the carrier resin, then plasticized by a two-roll plasticizer (also known as a twin-roll mill), and finally granulated by a single screw or twin-screw extruder.

2. Flushing method is to grind pigments, water and dispersants through sand to make pigments less than 1 micron in size, and to transfer pigments into oil phase by phase transfer method, and then to dry them to make color masterbatch. Organic solvents and corresponding solvent recovery devices are needed for phase inversion.

3 kneading method is to mix pigments with oily carriers, and make use of the oil-affinity of pigments to wash pigments from aqueous phase into oil phase by kneading. At the same time, the surface of the pigments is coated by an oil carrier to make the pigments disperse stably and prevent the pigments from agglomerating.

4 Metal soap method is that the particle size of pigments is about 1 micron after grinding, and soap liquid is added at a certain temperature to make the surface layer of each pigments evenly wetted by soap liquid, forming a layer of saponification liquid. When metal salt solution is added, a layer of protective layer of metal soap (magnesium stearate) is formed by chemical reaction with the saponification layer on the surface of pigments, so that the fined pigments will not be ground. It causes flocculation and protects a certain degree of fineness.

Notices for Use of Color Masterbatch

(1) The Color Masterbatch will absorb moisture after storage for a period of time, especially PET, ABS, PA, PC, etc. Therefore, it should be dried according to the same process of the color masterbatch and meet the requirement of water content.

(2) It is necessary to be very careful to use color masterbatches to achieve the desired color and lustre, which often results in changes in color difference and color light.

(3) Colour masterbatch and other additives will react, when using, pay attention to.

(4) Attention should be paid to the selection of dilution ratio of masterbatch. Choosing high dilution ratio will result in lower production cost, but it will also be limited by processing equipment.

The above is all about the production of color masterbatch with which the requirements of the article to share.

Printing

Printing Collect this page

Collect this page

Share to:

Share to: Recommended reading

Recommended reading

粤公网安备 44030502006867号

粤公网安备 44030502006867号